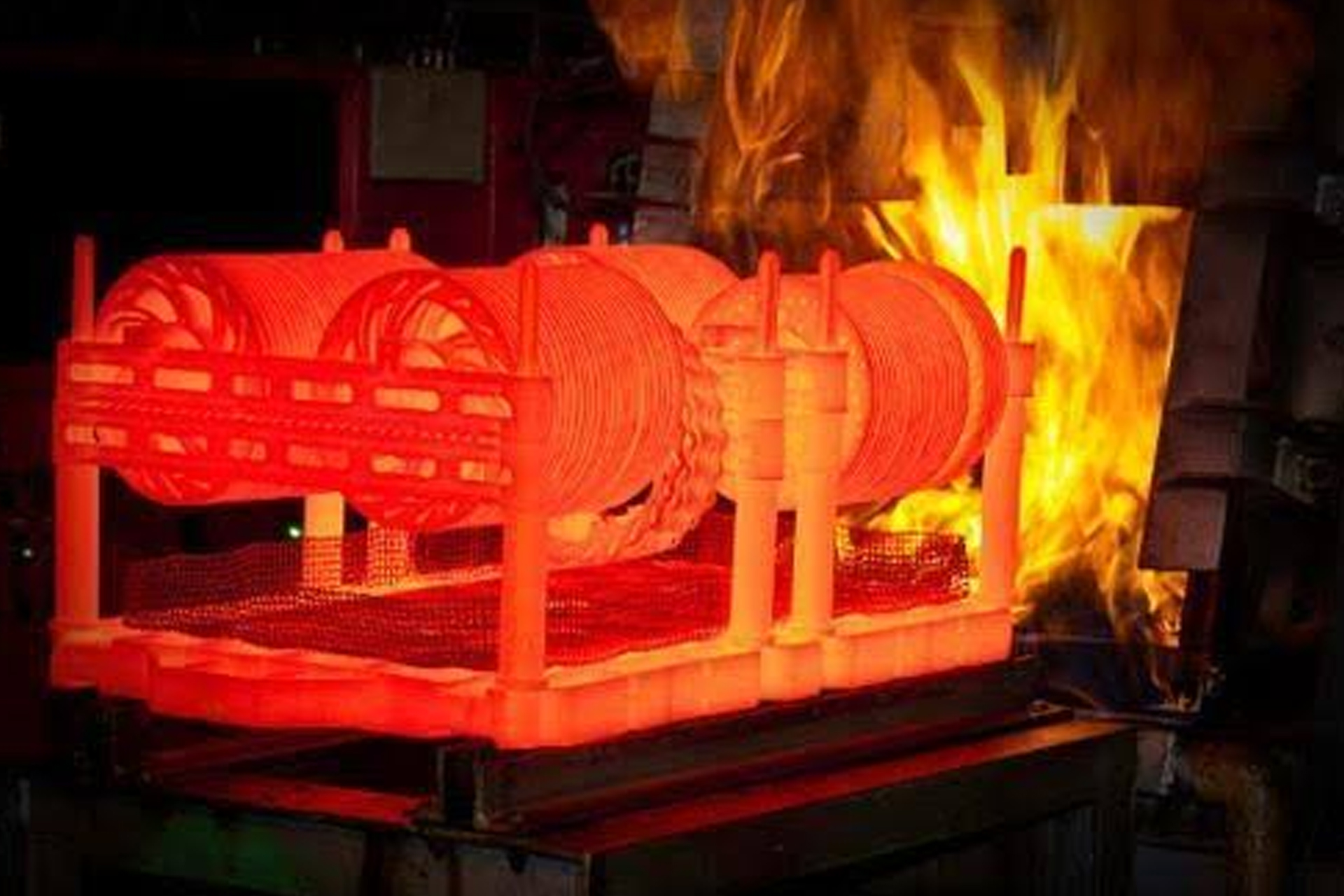

Pre-Heating & Stress Relieving

Pre-Heating & Stress Relieving

The ability to tailor properties by heat treating has contributed greatly to the usefulness of metals and their alloys in an assortment of applications such as sheet metal for cars and aircraft.

Regardless of the reason for the heat treating, the basic process is the same and has three steps.

– Heat the metal to a specific temperature

– Hold the metal at that temperature for a specific amount of time

– Cool the metal in a specific manner

Basic Processes

– Annealing

– Normalizing

– Stress Relieving

– Tempering

– Hardening

Annealing

Annealing is the process for softening materials or to bring about required changes in properties, such as machinability, mechanical or electrical properties, or dimensional stability. The annealing process consists of heating the steel to or near the critical temperature (temperature at which crystalline phase change occurs) to make it suitable for fabrication.

Normalizing

Normalizing is a heat treatment process for making material softer but does not produce the uniform material properties of annealing. A material can be normalized by heating it to a specific temperature and then letting the material cool to room temperature outside of the oven. This treatment refines the grain size and improves the uniformity of microstructure and properties of hot rolled steel.

Stress Relieving

Stress Relieving consists of heating the steel to a temperature below the critical range to relieve the stresses resulting from cold working, shearing, or gas cutting. It is not intended to alter the microstructure or mechanical properties significantly also a process for making material softer. However stress relieving does not change the material properties as does annealing and normalizing. A material can be stress relieved by heating it to a specific temperature that is lower than that of annealing or normalizing and letting it cool to room temperature inside or outside of the oven. This heat treatment is typically used on parts that have been severely stressed during fabrication.

Tempering

Tempering is carried out by preheating previously quenched or normalized steel to a temperature below the critical range, holding, and then cooling to obtain the desired mechanical properties. Tempering is used to reduce the brittleness of quenched steel. Many products that require hardness and resistance to breakage are quenched and tempered. The temperature chosen for the tempering process directly impacts the hardness of the work piece.

Case hardening

Case hardening or Surface hardening is the process of hardening the surface of steel while

leaving the interior unchanged. The idea behind case hardening is to have two different types of steel in the same item. This allows a relatively soft, tough core of a component to be combined with a hard (but potentially brittle) surface. Case hardening improves the wear resistance of machine parts without affecting the tough interior of the parts.

Aerotech heating systems gives all the above mentioned services with very systematic, calculated way to make the service flawless and qualitative.

Address

Jankpuri Society,Nigam Socitey Road,

Ghodasar,Ahmedabad,380050

We Serve Everywhere